Main Attractions of Aura Max

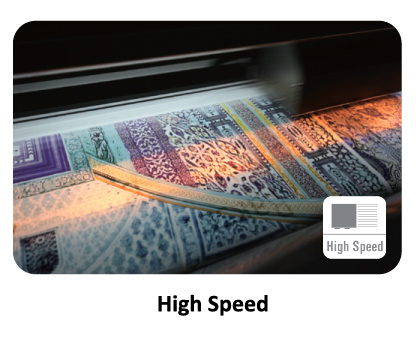

- Speed more than 80 sq.mtr./hr.

- Economical Production

- Low Maintenance cost

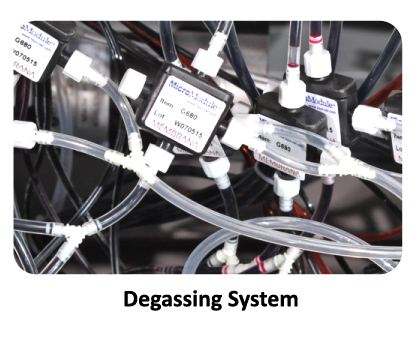

- Positive ink pressure system

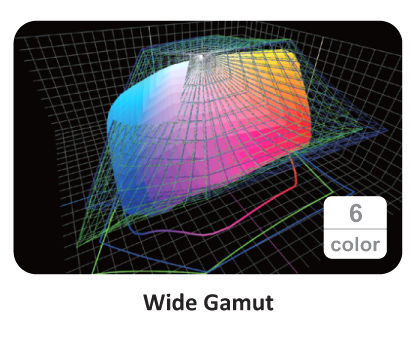

- EPSON 6 Colours printhead

- Higher resolution & Wider Gamut

- Four print heads giving higher speed

- Robust Design

- NeoStampa Rip Software

- Variable dot

- True Colours, Sharpest Prints & Consistency

- CTPC System

- Pallet Printing & Roll to roll

- Adjustable Height

Specifications |

|

|---|---|

| Print system | |

| Printhead type | Micro piezo technology, gold generation printhead |

| Ink droplet size | Variable droplets, 1.5~27pl |

| Printhead | 4X Epson 6 channel gold generation printhead, 300 nozzle per channel, single flow valve, No dampers, High Resolution. |

| Number of nozzles | 9600 nozzles |

| Ink colour | 6 Colors (CMYK+OB+LmLk) |

| Printing width (cm) | 180 |

| Height Adjustment | 5cm |

| Speed (64” width, small Enclosion) | |

| 360X1200dpi | 70 sq. mtr per hour |

| 360X1800dpi | 50 sq. mtr per hour |

| 720X1200dpi | 38 sq. mtr per hour |

| Ink supply & ink | |

| Ink supply type | Unique positive ink pressure system for EPSON printheads |

| Ink tank | 5 liter/colour |

| On-line degassing system | 3M Membrena® USA improves the inks runability & breaks the air bubbles in the ink |

| Ink type | Reactive / Disperse / Acid / Pigment |

| Structure and Function | |

| Roll to roll type | Yes and Pallet Printing |

| Opening Roller | Fabric is fed through this roller to ensure correct tension and opening |

| Pneumatic Feed & Fabric Take-up | Ensure even fabric tension |

| Under Fabric Heater and Tunnel Dryer | Quick drying of fabric for higher speed |

| Low ink warning alarm | Yes |

| Software & System | |

| Operating system | Windows7 64bit (Recommended) |

| RIP software | NEOSTAMPA (Recommended) |

| Voltage | AC220-240V 50-60HZ or AC110-120V 50-60HZ |

| Operating environment | Temperature: 15~25 degree centigrade; Humidity : 60~70% |

Aura Max 1800

| Mechanical Structure | |

| Belt system | Using Habasit® insdustrial belt, an adhesive belt transport system, with edge aligment. |

| Belt Cleaning Unit | The washing Unit in stainless steel, a rotating brush washing unit with open water circuit prevents 'back printing' by removing the excess of ink from the adhesive blanket. The entire Washing unit is mounted on rolls and can be extracted with ease for inspection and cleaning. |

| Hot air infrared dryers | A hot air infrared dyer just after the washing unit to dry out traces from the belt, and pre-heat the blanket's surface to optimal working temperature of the themoplastic adhesive. |

| Lighting | LED lights for platform + Lazer guide |

| Feeder & Take-up | |

| CTPC | Constant tension pasting cloth device for knitted fabric, it can give a low, constant tension into the knit |

| Enhance take-up | it has a wide range of tension adjustment, roll diameter 400mm, more than 100kg. |

| Expander Roller | The expander roll can remove wrinkles, while opening the fabric, the fabric will be smooth. |

The data here is subject to change without prior notice & is only for reference